Bossard collaborated with an OEM and its tier supplier team to achieve precise electrical insulation and packaging tolerances while cutting costs in tooling, molding, and assembly.

In the electric vehicle sector, manufacturers often manage design and assembly internally but rely on tier suppliers for production. This split responsibility can create inefficiencies and expensive trial-and-error cycles, impacting product quality and long-term maintenance. A leading North American truck OEM faced these very challenges in an electric truck program. Working closely with both the design and manufacturing teams, Bossard North America engineered a custom insert-stud fastening solution for the vehicle’s battery system — one that ensured tight dimensional control, electrical reliability, and efficient assembly.

Overcoming Tight Space and Clearance Challenges

Battery systems in commercial EVs demand compact, lightweight layouts. Designers must fit numerous components — including connectors, wiring, and busbars — into limited space while maintaining the electrical clearances necessary for durability and safety. These constraints often push the boundaries of polymer design and tooling feasibility.

To meet these conditions, Bossard developed a specialized insert-stud fastener that secures electrical components to a polymer carrier. The design balances electrical isolation, mechanical strength, and manufacturability, allowing for a practical molding solution without overcomplicating the tooling process.

Material Knowledge Driving the Design

Reinforced polyamides such as PA6 and PA6.6 are commonly used in EV battery enclosures for their mechanical integrity and insulating properties. Drawing on extensive experience with these materials, Bossard’s engineering team proposed fastening concepts that minimized back-and-forth between the OEM’s design group and the injection molder.

By understanding how insert geometry affects factors like pull-out resistance and torque limits, Bossard ensured that the proposed solution would deliver the necessary performance under demanding thermal and mechanical conditions.

A Tailored Solution for Manufacturing Efficiency

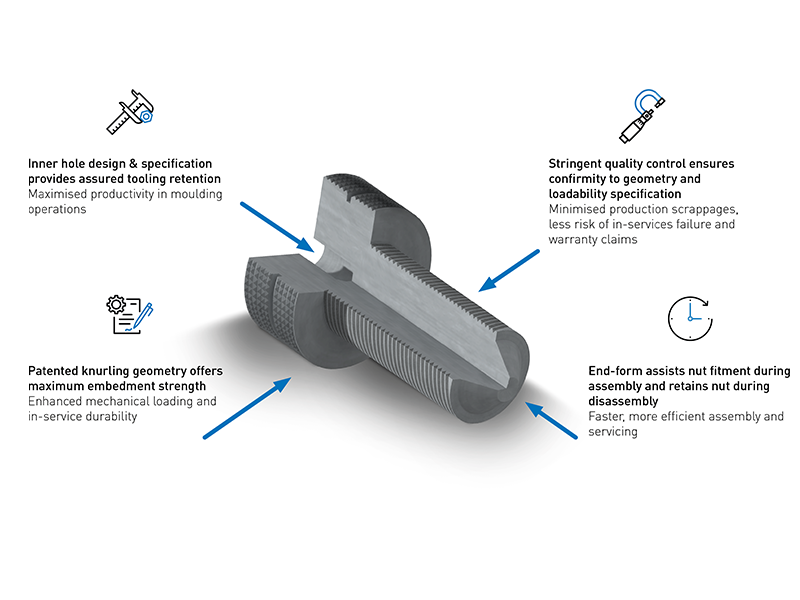

Conventional insert installation methods using external threads were not feasible due to tight packaging and limited clearance. To address this, Bossard partnered with tooling engineers to design a custom core-pin retention geometry directly into the insert stud. This design allowed secure placement during molding and maintained compatibility with standard manufacturing practices.

Achieving Assembly Load Requirements

Maintaining target torque levels for fasteners such as property classes 8.8 and 10.9 was another critical requirement. Simply scaling up the fastener size wasn’t an option — doing so could interfere with nearby components or compromise insulation spacing.

Bossard overcame this through a patented knurling configuration that maximized mechanical engagement with the polymer material. Finite element simulations confirmed load performance, while early CAD collaboration streamlined clearance verification. Regular coordination with tooling specialists ensured all pin geometries were feasible for mass production.

Customer Benefits

Accelerated development:

Bossard’s upfront design support reduced costly iterations, shortening the path from prototype to production.

Improved manufacturing reliability:

The engineered solution minimized risks of tooling wear, part rejection, and downstream quality issues.

Simplified coordination:

By serving as a single technical interface between design and manufacturing teams, Bossard ensured alignment on specifications and performance targets throughout the project.